Feed conversion is one of those production metrics that is many times used as the discussion and relative comparison point from one operation to the next or one group of pigs or birds to the next. We all want to be able to talk about low feed conversion numbers. Feed conversion is the calculation of how much feed it takes to put on one pound of body weight and many factors can cause significant change in the feed conversion that is calculated following the close-out of a group. Monitoring feed conversion is important, and especially important with ingredient prices where they have climbed to in early 2021. Any and all things that may improve feed conversion should be evaluated as the cost savings could be significant. On the other hand, spending money to “buy” a low feed conversion where not cost effective only returns bragging rights. I’ve listed a few of the drivers of feed conversion below for your consideration and will discuss some of them in this article.

-

- Diet energy level (fat addition or use of other feed ingredients)

- Grain micron size (related to the above)

- Sex of pigs

- Paylean use

- Genetics

- Feed wastage

- Accuracy of meeting nutrient requirements/feed quality

- Average daily gain (F/G will improve with improving ADG)

- Livability

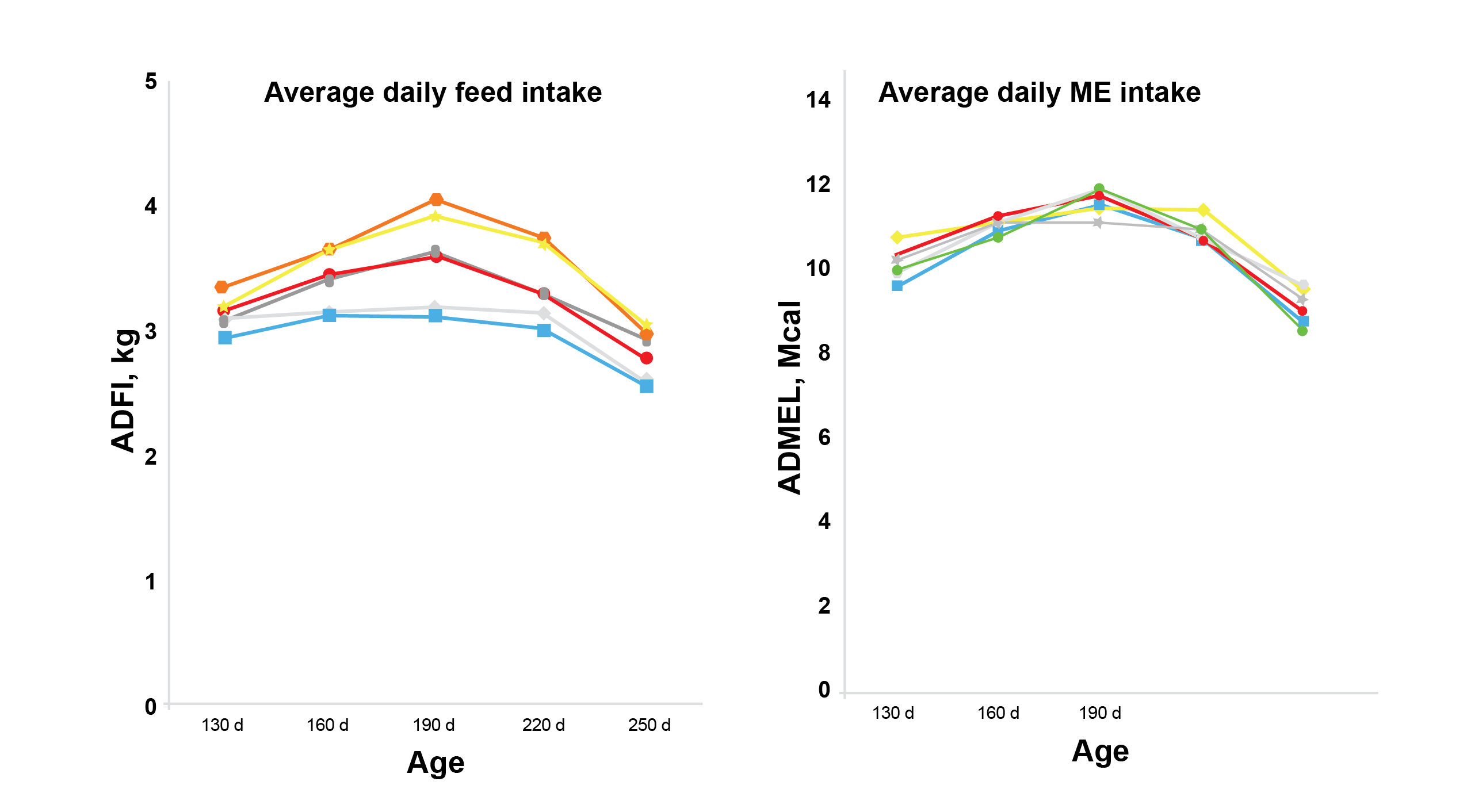

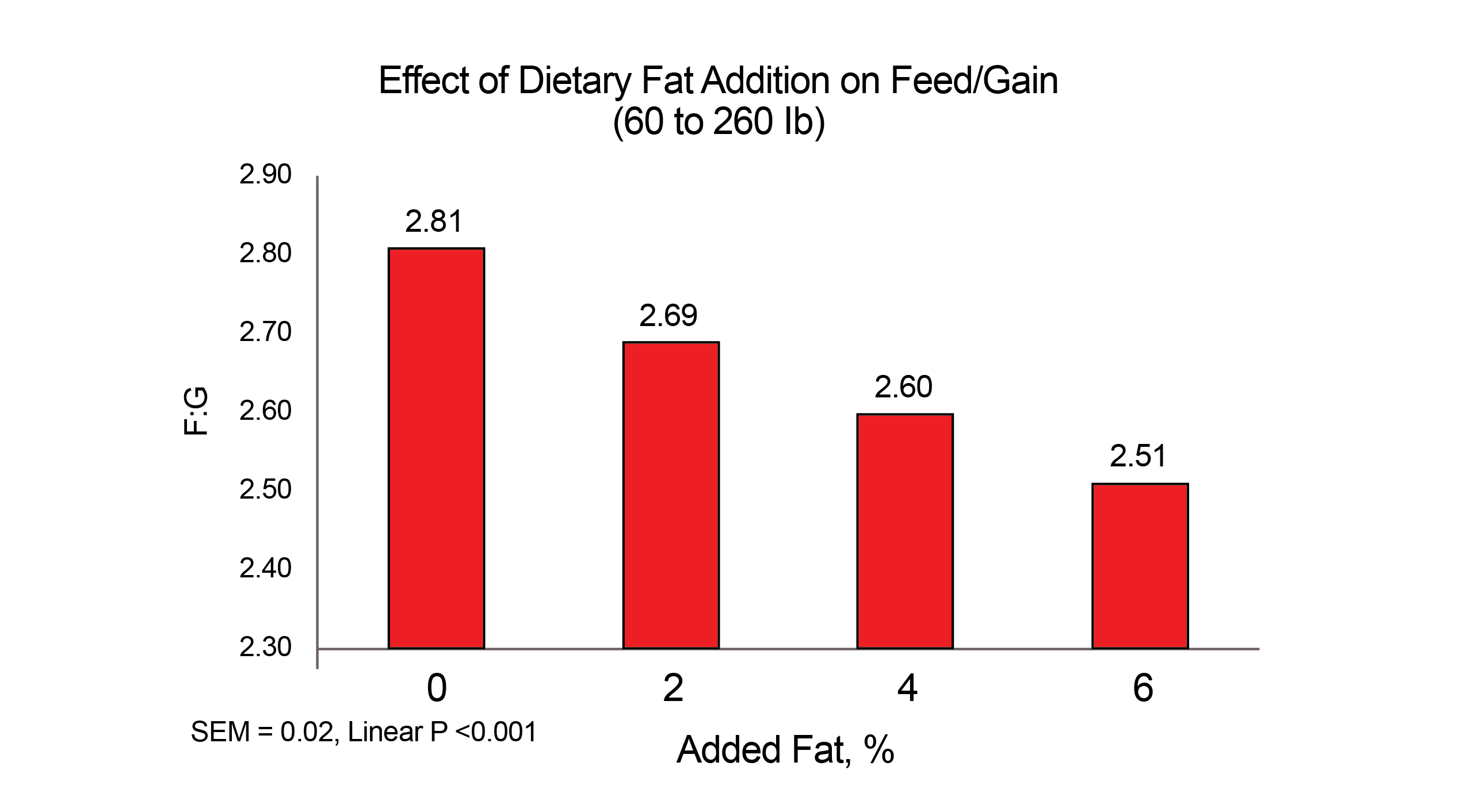

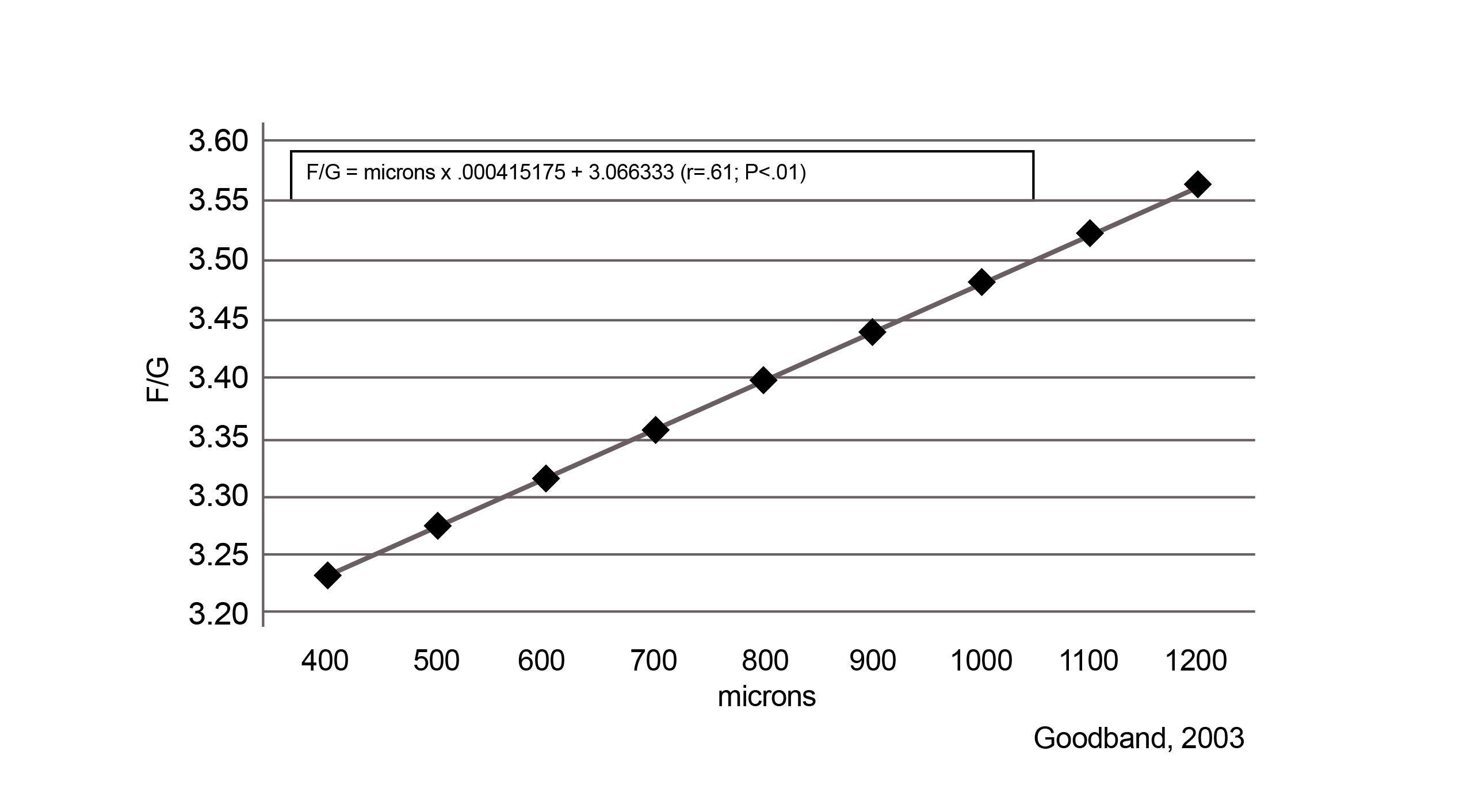

One of the best visuals I can use to start this discussion is shown in Figure 1. These are results from National Pork Board sponsored study evaluating gilt development strategies to improve sow lifetime productivity. The diets fed to these six groups of gilts were formulated at three different in dietary metabolizable energy (ME) levels. This energy difference in the diet could be caused by a number of different methods such as adding fat, using low energy ingredients, changing corn micron size etc. The interesting thing you will notice is that when the gilts were fed the diets of varying ME content, they changed their feed intake to meet their ME requirement and so as we consider daily ME intake, there is no difference between the groups of gilts. However, as you can imagine, the feed conversion of the gilts fed the low energy diets would be higher than those fed the high energy diets (i.e., feed intake was higher to achieve the same energy intake and thus daily gain). If we stop our evaluation here, we would conclude that we should feed high energy diets and achieve improved feed conversion. However, an important next step is to apply the economics of creating feed conversion change to make sure it is the right decision for profitable production. Figures 2 and 3 provide examples of very predictable feed conversion change when fat is added to the diet (increased energy) or micron size of the corn is changed (change in energy).

Figure 1. Daily Feed Intake and Resulting Metabolizable Energy (ME) Intake of Gilts Fed Diets with Variable ME Content (Vallet 2016)

Figure 2.

Figure 3. Effect of Corn Micron Size on Finishing Feed Conversion

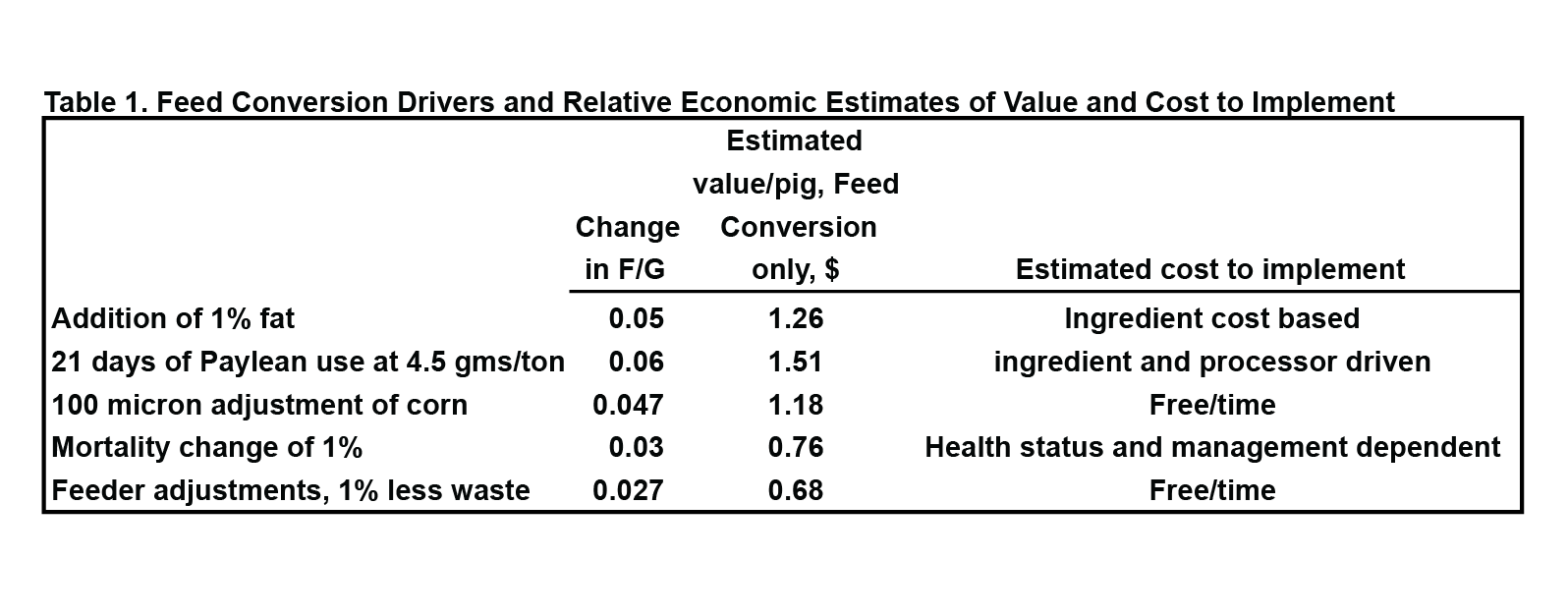

To allow us to consider the economics of feed conversion change I’ve provided in table 1 some examples of feed conversion drivers and estimates of the magnitude of change along with the estimated value. I’ve included thoughts on estimated cost to implement. Each of these costs are location specific but are easily calculated. Please note that there are two drivers that can have significant impact on the feed conversion result (and value!) but cost very little if anything to implement.

The profitability of pork production is the metric to focus on for long term viability of your operation. Please contact your Standard Nutrition Consultant if you are interested in evaluating any of these opportunities at your specific location.