By: Bart Borg

In our last article, we discussed the value of corn micron size for the growing pig relating to feed conversion improvement. In this period of high-priced corn, it is very important to monitor and manage grind quality targets both for average micron size and variability. As we see with the growing pig, we know there is an impact of particle size on the breeding herd as well. This article will present a method to establish a value of particle size change for the breeding herd. While the experimental information to base the value on is not as large as the number of experiments for the growing pig, we can use some basic biological assumptions to use the information from the growing pig to model the value for the breeding herd.

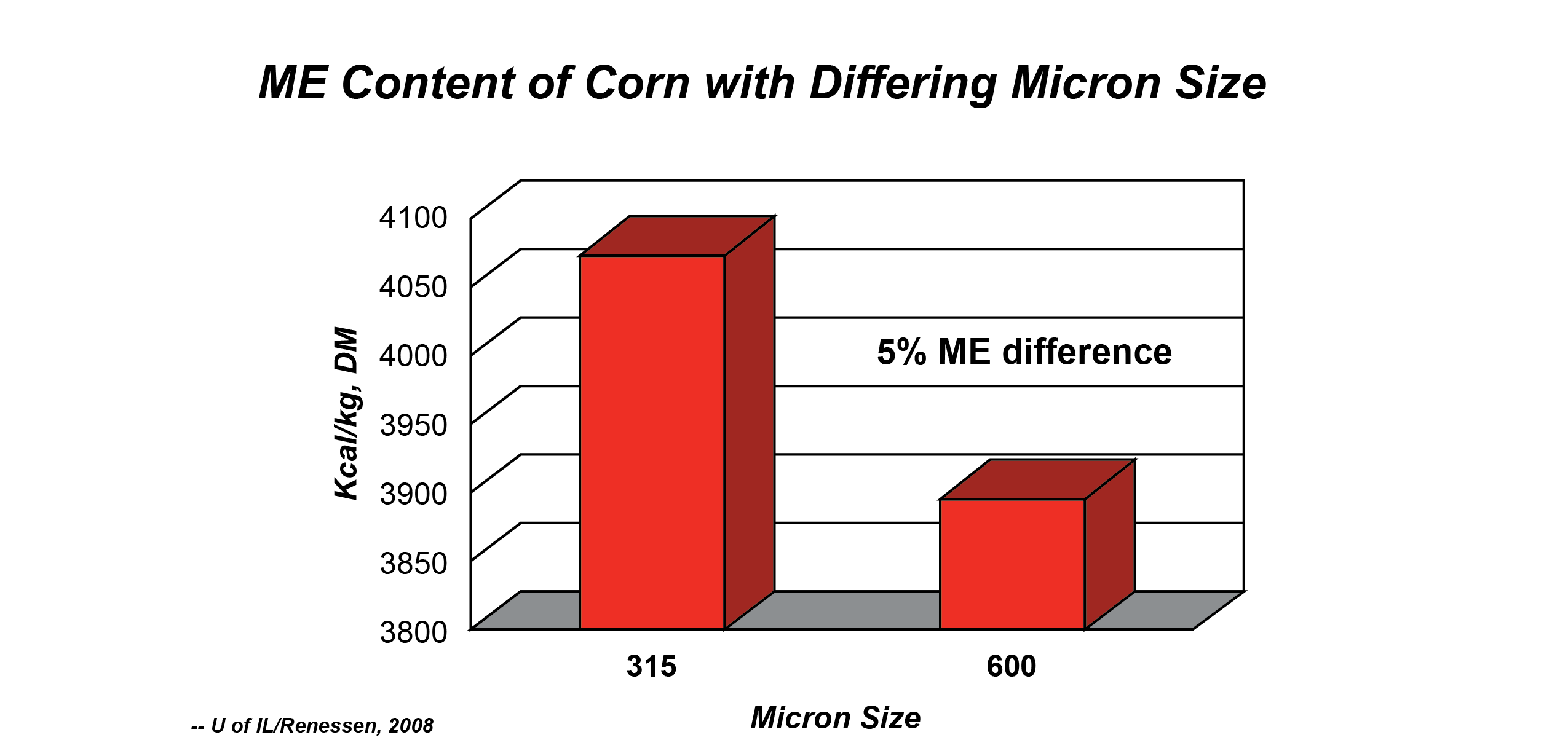

As a quick review, micron size is important to pay attention to as it is a driver in the amount of energy that the pig will extract from corn. The finer the corn (lower the micron size) the greater the overall digestibility of the corn. The chart below shows the improvement in energy availability for corn that is ground at about a 300 micron difference. As you can see, the metabolizable energy available for the pig consuming a diet with lower micron corn is 5% greater than that diet with higher micron corn. This doesn’t seem that significant, but if you do the math on dietary energy costs, etc., it does show significant value. This same improved digestibility occurs for the mature sow in both gestation and lactation diets. Corn ground to a lower micron will provide a greater amount of energy per pound of corn. We often discuss the value of adding fat to a lactation diet or strategies to get more feed consumption by the lactating sow. Both of these strategies are desired for the same reason that reduced corn micron has value, increased energy consumption leads to more milk production and ultimately increased litter wean weights.

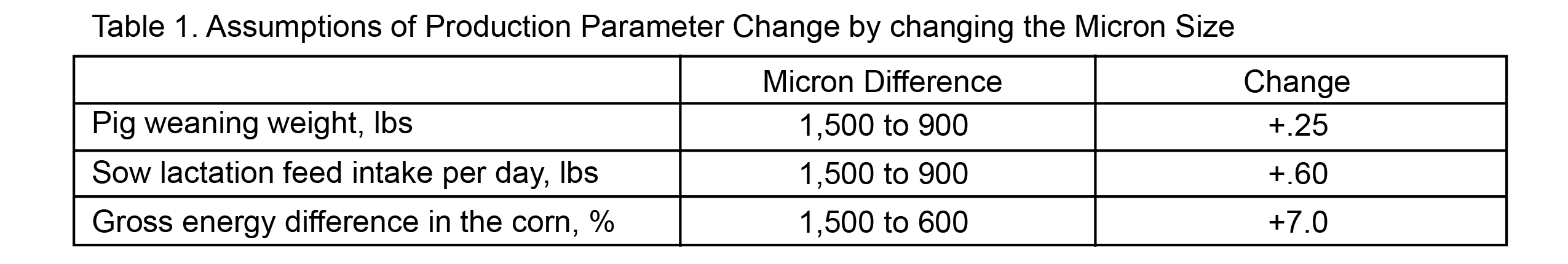

To calculate the value of micron size for the breeding herd we can reference a trial conducted at Kansas State University that set out to define the differences in sow productivity and feed digestibility when corn micron varied from 1,500 microns to 600 microns. The basic assumptions of change from that study are shown in Table 1.

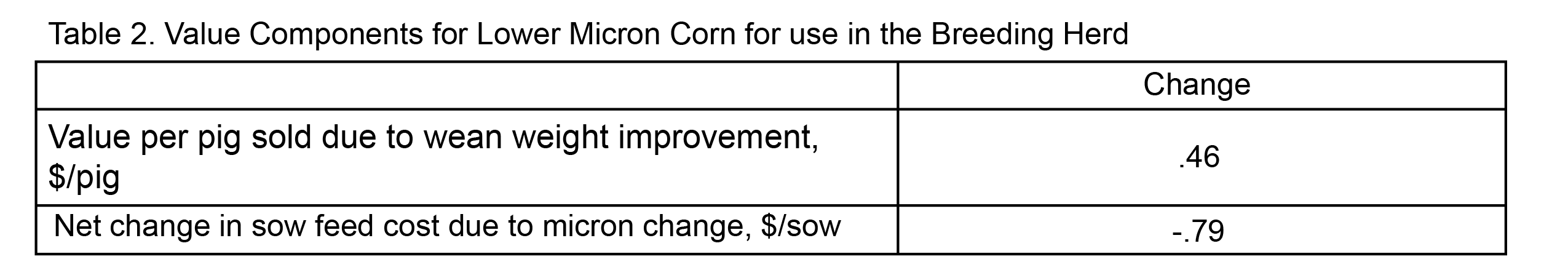

After settling on these benefits, it is simply a calculation of value based on the changes listed above. Added wean weight leads to improved grow-out performance, lower mortality, and improved feed conversion. Additional lactation feed consumption (this is shown as a benefit in other trials too) is a benefit, but also comes at a cost, so this added lactation feed cost is considered. Energy value in the corn can mean diet cost savings or simply increased energy intake. For gestating sows, this means less feed needs to be fed to maintain condition when corn micron size is lower. This cost improvement is also considered.

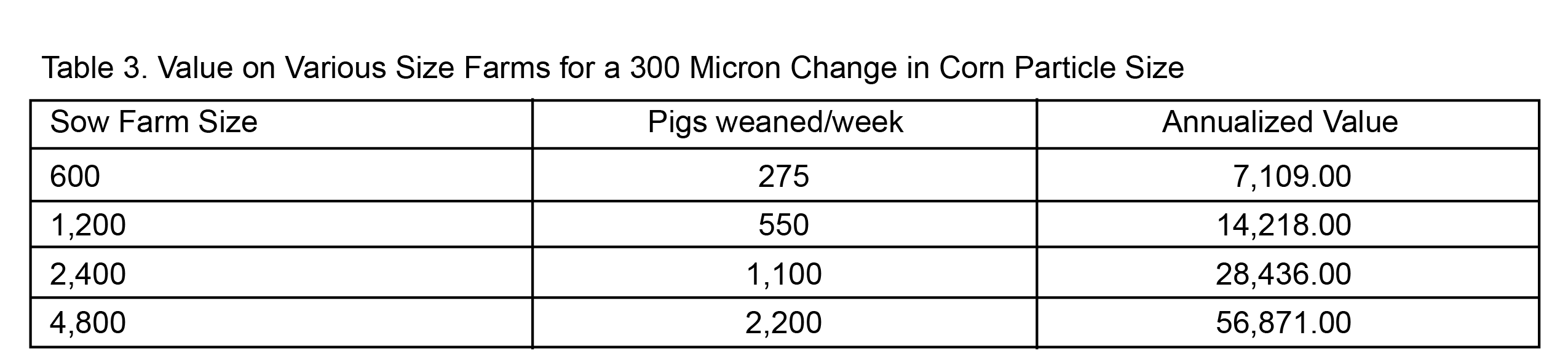

Listed in table 2 are the individual value components and Table 3 shows an estimated annualized value for a 300 micron change in corn micron size for the breeding herd.

Corn micron size is an important area of feed quality control and not optimizing around this can be an expensive mistake. Our suggestion for corn micron size for the breeding herd is similar to the micron size suggested for the growing pig. For corn processed with a roller mill we suggest targeting 575-600 microns and with a hammer mill 675-750 microns. The standard deviation target is 2.2 or less. Standard Nutrition Services offers particle size analysis as a service and will be happy to help you consider a sampling protocol for your mill or feed supplier. Although the digestibility advantages in swine are significant, we understand that where multispecies are being fed from a single mill it can be challenging to select the “optimum” particle size. For example, in turkey production, a coarser particle size is preferred. We look forward to working with you to help determine the optimal path for your operation.